A sheet metal bending and mechanics of spring back.

Bending force problem sheet metal.

Under the force of bending the plate along the lower die v groove edge movement and bear the squeeze and friction generated by the bending force so that the surface of the formed sheet metal has distinct bending marks defect the width of the defect place is about 0 414 times the width of v groove seriously affecting the appearance of the.

Sheet metal bending bending of sheet metal is a common and vital process in manufacturing industry.

This is done through the application of force on a workpiece.

The force of the bending moment determines the degree of deformation.

Even on malleable materials you can end up cracking the metal at the bend or weakening it to the point where it ll break with minimal force.

Minimum bending radius is a function of the.

Similar to other metal forming processes bending changes the shape of the work piece while the volume of material will remain the.

The notation used in the text l w differs from that used in the previous development b l.

Commonly used equipment include box and pan brakes brake presses and other specialized machine presses typical products that are made like this are boxes such as electrical enclosures and rectangular ductwork.

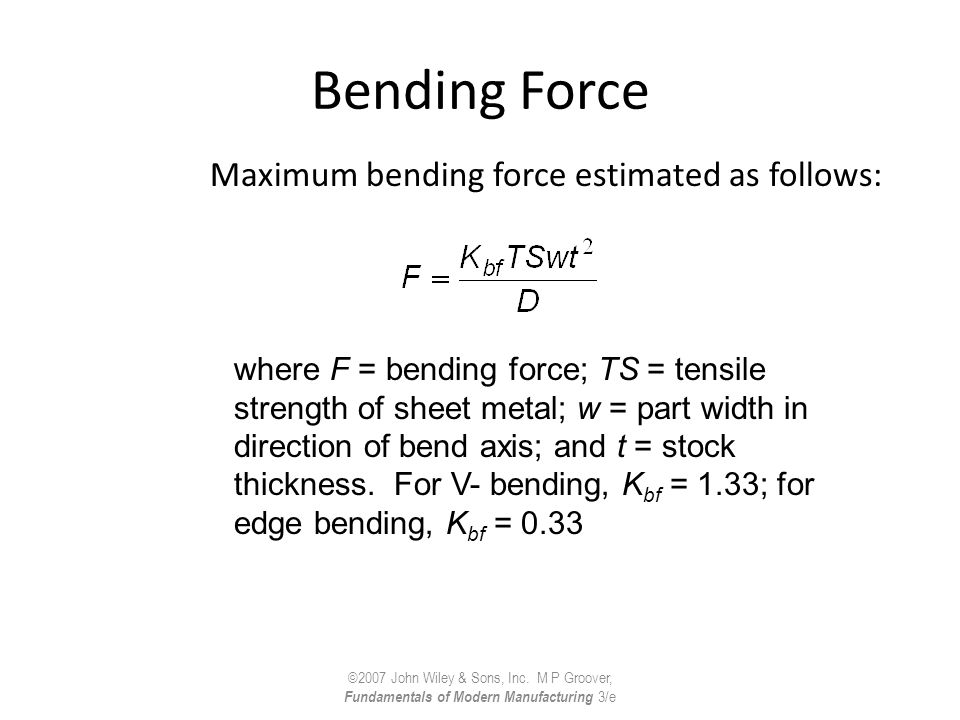

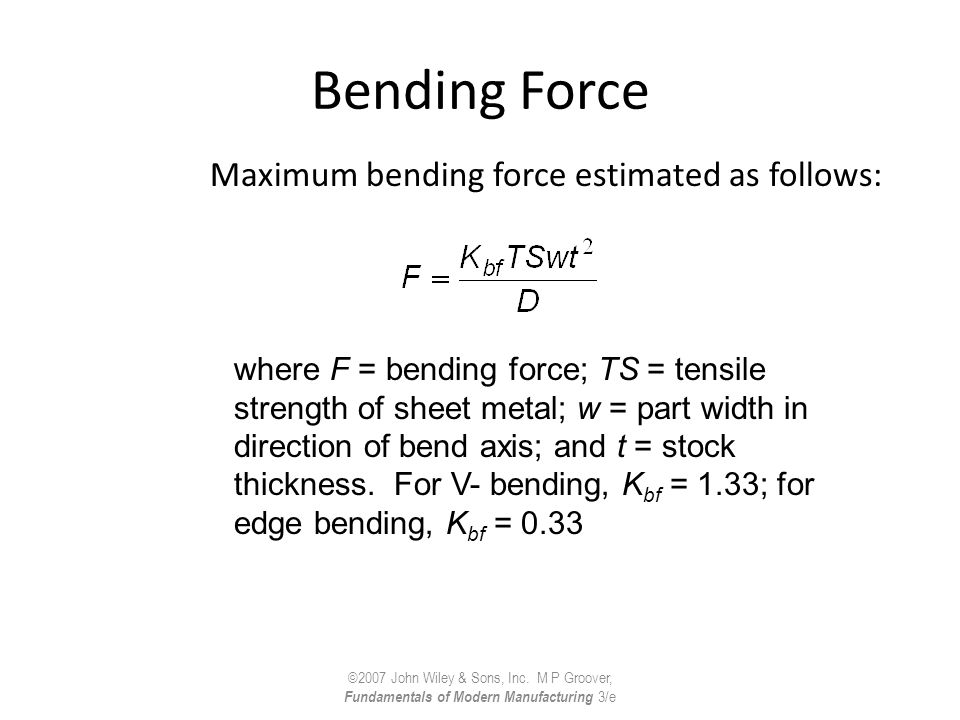

Bending force requirement punch workpiece t die w force t sheet thickness w width of die opening l total length of bend into the page uts ultimate tensile strength of material 2 uts w lt f note.

Bending is one of the most common sheet metal fabrication operations.

Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape.

Bending is the forming of sheet metal by application of force which exerts pressure on a certain length of material either at a certain point or linear as an evenly distributed weight.

This applied force is also called the bending moment.

Bending and forming of the metal sheet are carried out on a plate bending machine.

B modeling of sheet metal bending process sheet metal type and methods are clearly and briefly credible reviews of previous important literatures are briefly discussed here.

The force must exceed the material s yield strength to achieve a plastic deformation.

The solution is to have a radius on the tool that you ll be using to bend the metal.

If you bend to a sharp inside corner with sheet metal you ll be adding a ton of internal stresses.

A number of researches have been carried out on the sheet metal bending processes and the effects of spring back.

Bending is a manufacturing process that produces a v shape u shape or channel shape along a straight axis in ductile materials most commonly sheet metal.

The bending force can be calculated from the sheet thickness die opening bend length and the ultimate tensile strength of the material.